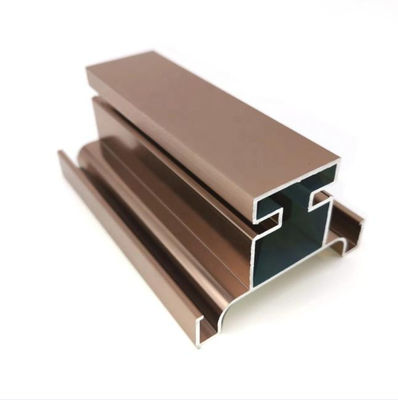

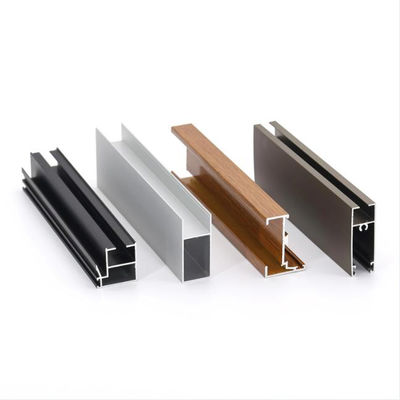

Wood Grained Aluminum Profile Extrusion for Kitchen Cupboard

Product Specifications

| Available Materials |

Aluminum 6063 |

| Finish |

Powder coating, Anodizing(Oxidation), Sandblasting, Brushing, Painting, Passivation, Silk screen, Polishing, Galvanise,(Nickel/Tin/Chrome/Copper) Plating, etc. |

| Payment Terms |

T/T : 30% before hand, balanced 70% before shipping |

| Industry Focus |

Appliance/ Automotive/ Agricultural/Electronics/ Industrial/ Marine/Mining/ Hydraulics/ Valves/Oil and Gas/ Electrical/ Construction/ machinery/furniture/ toy/ woodboard/ wall/ agricultural |

| Tolerance |

± 0.1mm |

| Section size |

Square: ≤ 150*150mm

Rectangle: ≤ 250*50mm

Round: ≤ ∅170mm

|

| Package |

Inner plastic paper/PE paper interleaving each piece;

Outer fixed by plywood or pallets with shipping mark;

Or as required.

|

| Lead Time |

Sample: within 10 days.

Mass Production: within 10-25 days after receiving the deposit

Rush Services Available

|

Our Manufacturing Advantages

We export the majority of our customized products to the United States and Europe, where our customers have become regulars. As a result of our long experience in this field, we can easily satisfy customers' needs.

- More than 17 years manufacturing experience in Aluminum Extrusion

- Strong design and extrusion capabilities with fast CNC machining, milling, and turning

- Complete metal processing facilities including stamping, laser cutting, CNC bending, and welding

- Strict quality control throughout the manufacturing process for long-term stability and excellent quality

Technical Support

- Custom design services including CAD drawings and 3D models for profile confirmation

- Design optimization by our R&D team to reduce costs and improve performance

- One-stop service from design to surface treatment with strict quality control

Factory Equipment Capabilities

Extrusion: 44 aluminum extrusion lines capable of producing profiles up to 350mm diameter, including a 6800 ton extruder for industrial profiles up to 600mm diameter.

Anodizing: 6 production lines producing uniform oxidation films in various colors with strict quality control.

Painting: 4 powder spraying lines using high-quality Swiss Gema nozzles and environmentally friendly paints.

CNC Machining: Advanced equipment including 12 PRATIC machining centers, automatic cutting machines, and various punching/bending machines for precision processing.

Packing & Shipping: Strict warehouse management with organized storage and quality inspection before delivery.

Certifications

Company History

2004: "The Recognized Brand of the Building Industry Material Market"

2006: "Certificate for Product Exemption from Quality Surveillance Inspection" and "ISO9001"

2009: "Advanced Company", "Jiangsu Famous Brand Certificate", "Certificate for Credible Product of Quality in Jiangsu Province"

2012: Established business relationships with Panasonic and LG

2015: Became innovative producer and supplying partner for European clients

2017: Developed new products of baseboard heaters

2019: Cooperated with world's largest heater manufacturers

2023: Expanding overseas distributor network

Notable Projects

The Soccer City Stadium in Johannesburg - Africa's largest stadium with 94,000 seats where we served as main aluminum supplier.

Lobster Trailers - Nordic trailer manufacturer where we provided design optimization and precision manufacturing.

School furniture project - Supplied aluminum legs for school desks through our strong design capabilities.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!